Retrofit – Fit for the future.

Expensive spare parts procurement, missing spare parts, severe wear and tear, system-relevant components that are no longer available, or increasing maintenance costs are reasons why retrofitting is worthwhile.

Would you like to evaluate, analyze, and document process data? Or save more energy in the future? Are energy costs an issue for you?

Then a retrofit is just the thing for your system.

You have been operating a coating system from our company for years. You have always repaired or replaced the mechanical and wear-prone components. You ensure regular and professional maintenance, thereby maintaining the value of your production equipment.

But what about the control system? Are all components still available on a one-to-one basis? Would you like to increase efficiency and operational reliability? Is energy consumption an issue for you?

Your answers to these questions may be arguments in favor of modernizing an existing plant.

Existing plants are brought up to date by replacing outdated components and adding technological enhancements. The advantage for the plant operator lies in the modernization of the plant and the associated increase in productivity, at significantly lower costs compared to purchasing a new plant. The stable basic structure of the plant remains intact. In the case of large plants, there is no need for high replacement investments for foundation construction.

Your advantages

- Ensuring the supply of spare parts

- Increase in plant availability

- Support for preventive maintenance

- increase in production volume

- Improving productivity and demonstrating it

- Lower operating costs for the systems, e.g. through energy savings

- Greater efficiency through process optimization

Our services

- Analysis of process problems and development of appropriate solutions

- Increase in plant efficiency

- End-to-end visualization of production processes

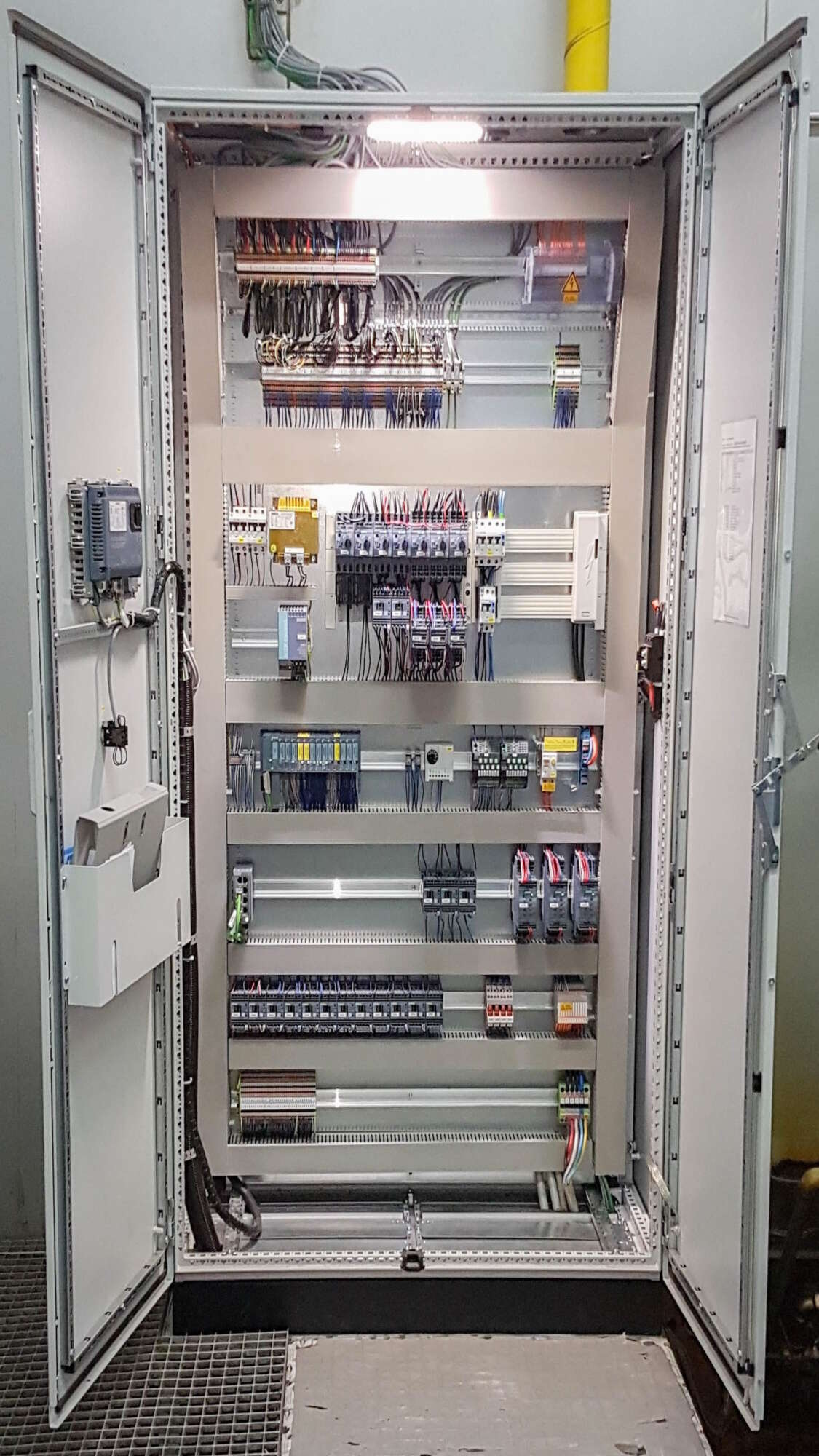

- Optimization of existing plant components

- Integration of new plant components such as modern coating systems, robots, feeding and removal systems, etc.

- Measurement, control, and regulation tasks

- Linking production facilities with upstream or downstream data processing systems (ERP, MES, etc.)

- Data acquisition and analysis of process data

- Software connection, latest PLC programming, and modern visualization

- Integration of remote maintenance elements

- Creation of valid, editable control documents and operating instructions

- Electrical, mechanical, and process engineering commissioning and optimization of your plant